Skip to content

GF auto-feed includes:

- 6m³ hopper with two perspex sight gauges

- 2 x augers and rotary valve

- Fully modulating burner fan for optimal efficiency

- Pneumatic stainless steel knife valves

- Boiler flue temperature monitoring

- Touch screen control panel

- Full delivery and Biomass boiler installation

Don’t just take it from us….

Take a look at what our customers had to say about the GlenFarrow auto-feed!

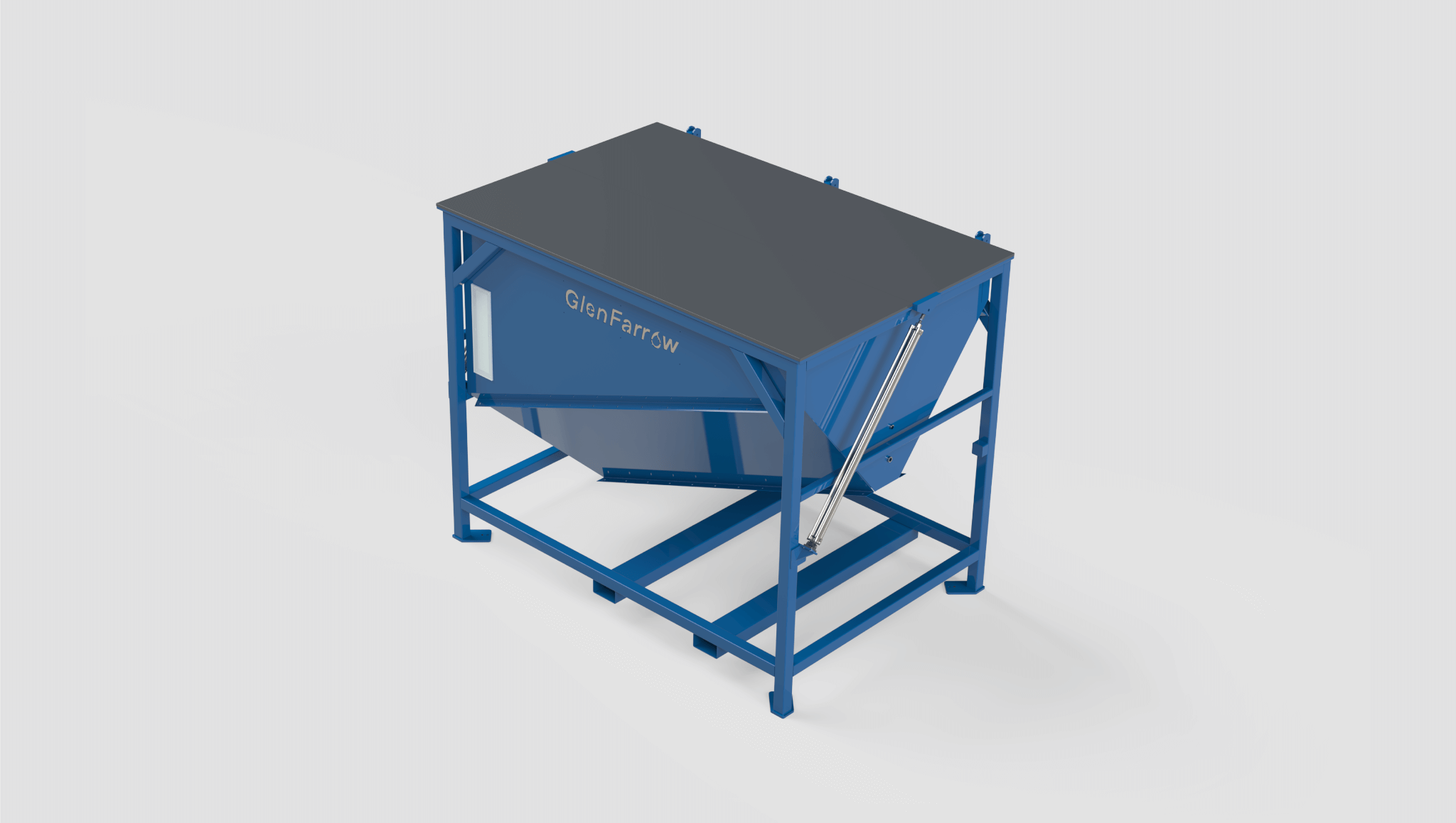

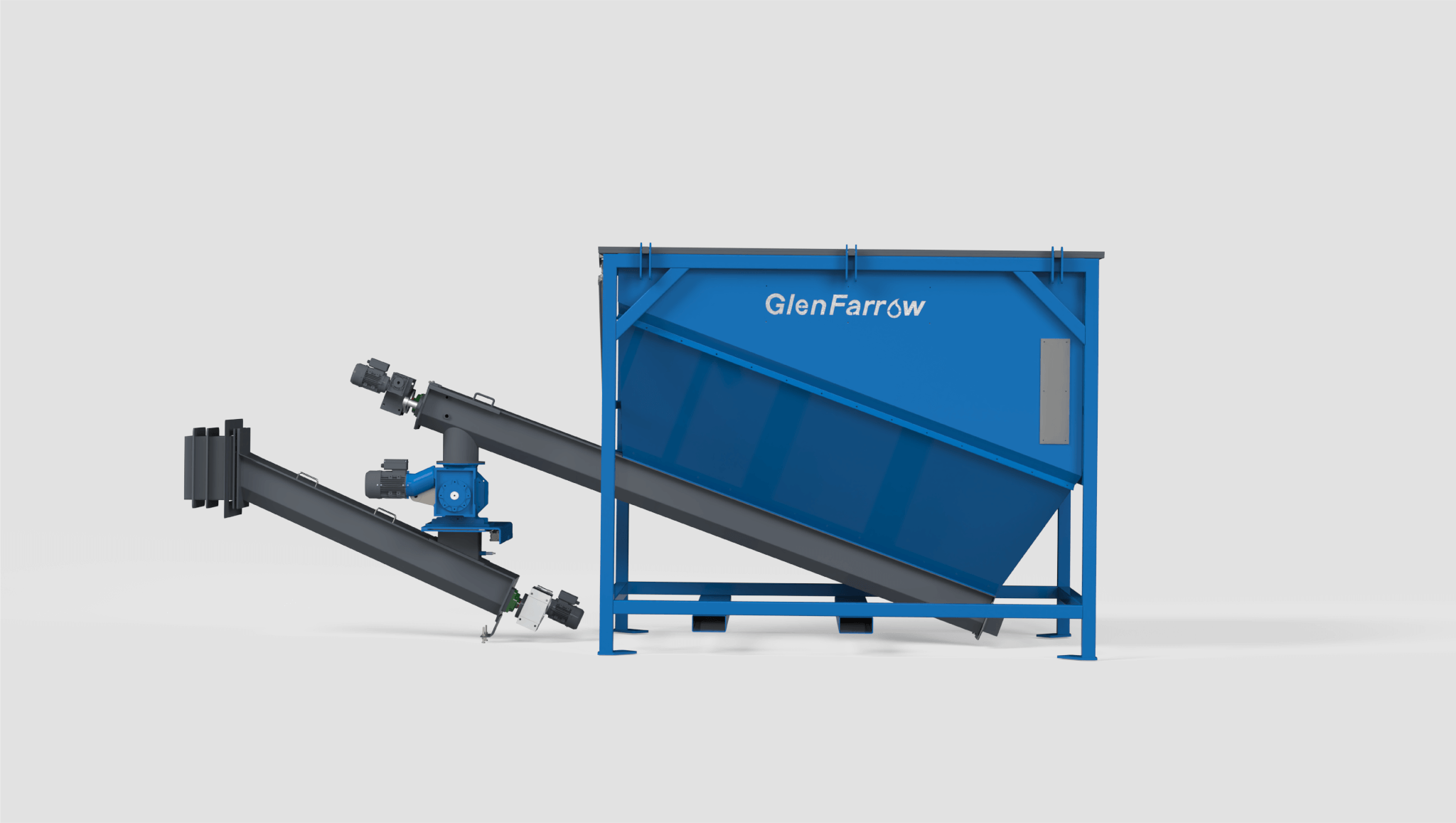

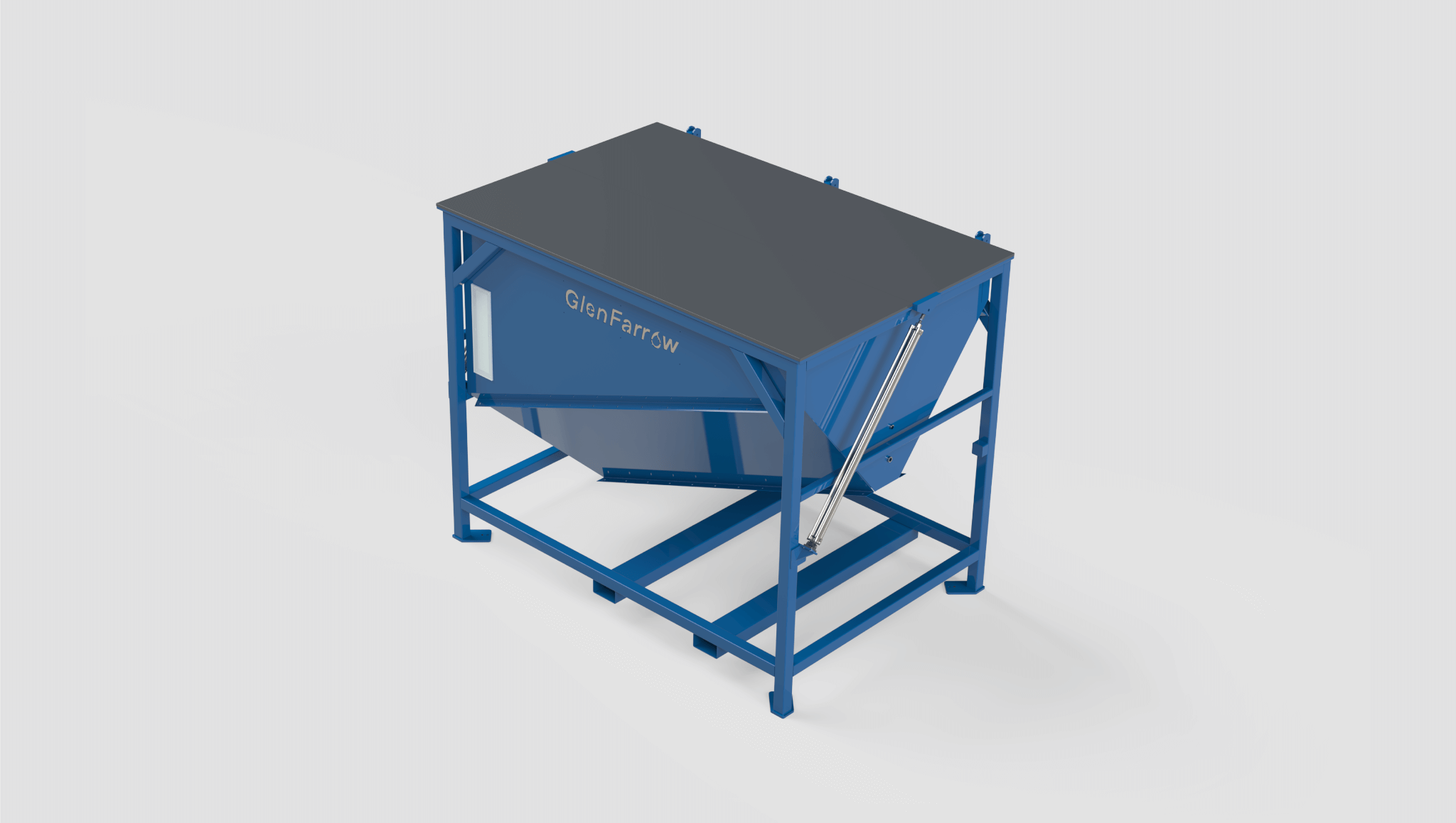

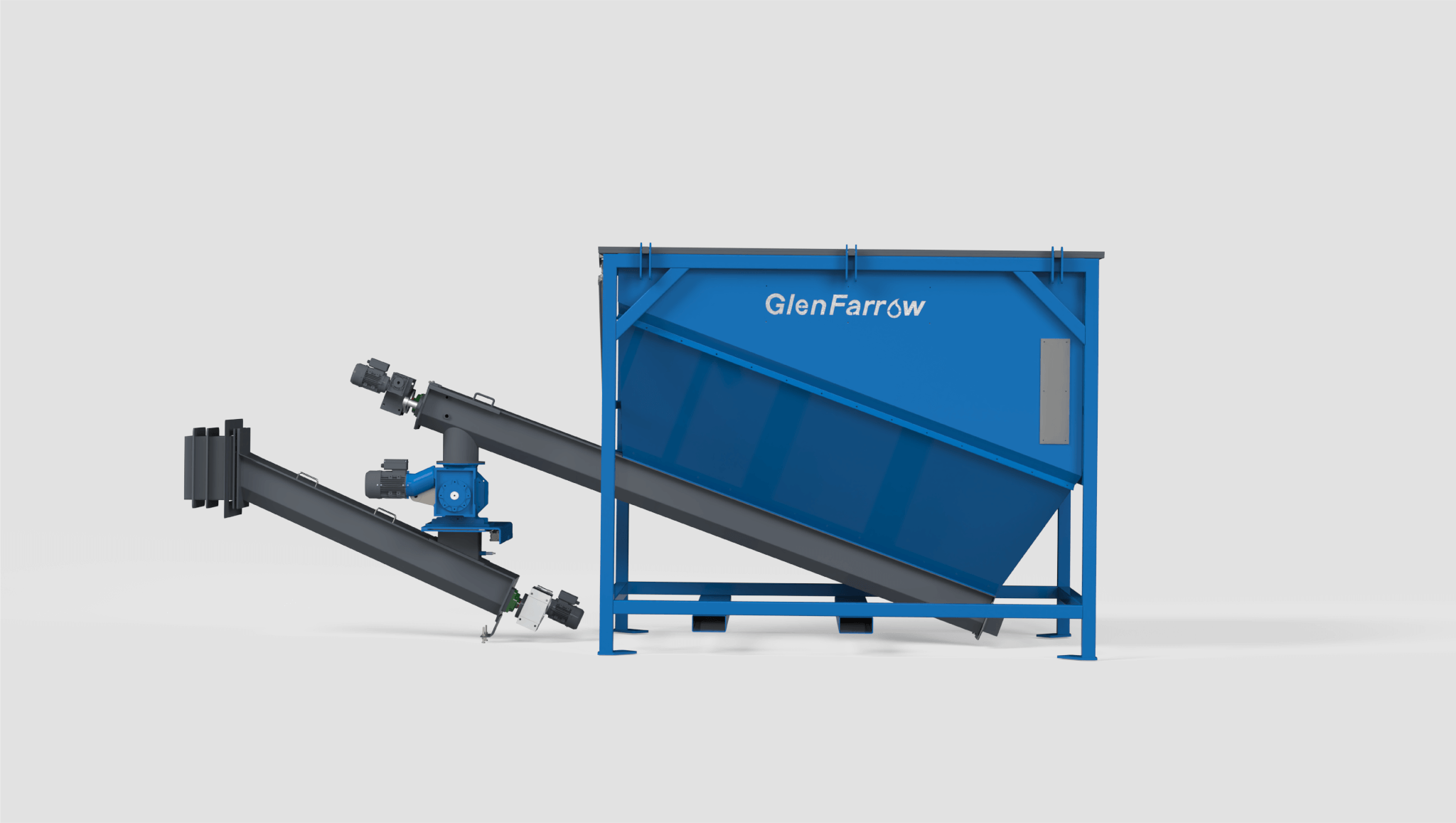

Stage one

The 6m³ hopper is filled with woodchip.

- 6m³ capacity

- All steel construction

- Two perspex sight windows

- Fully pneumatic, aluminium hopper roof which helps to weatherproof the system

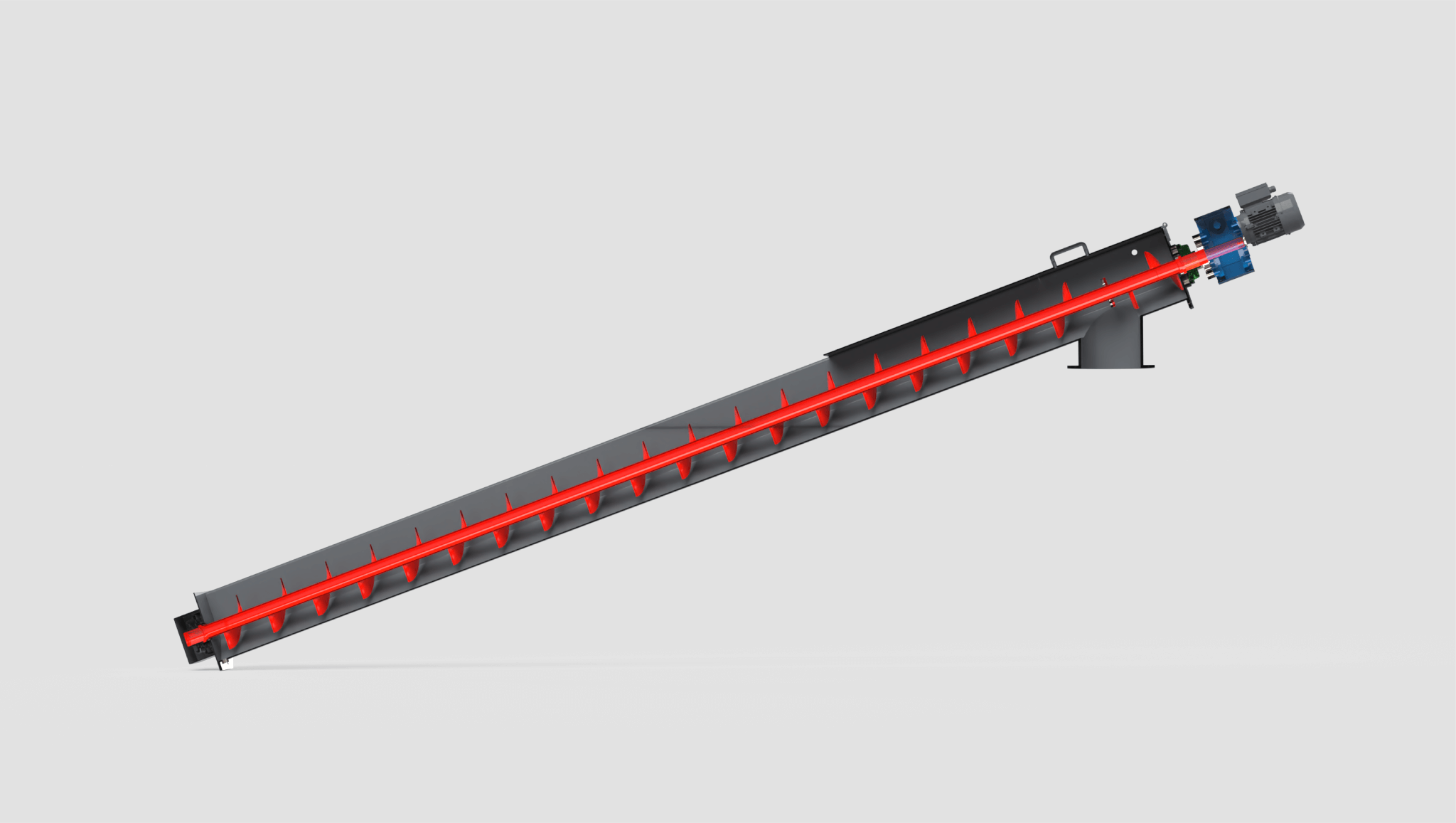

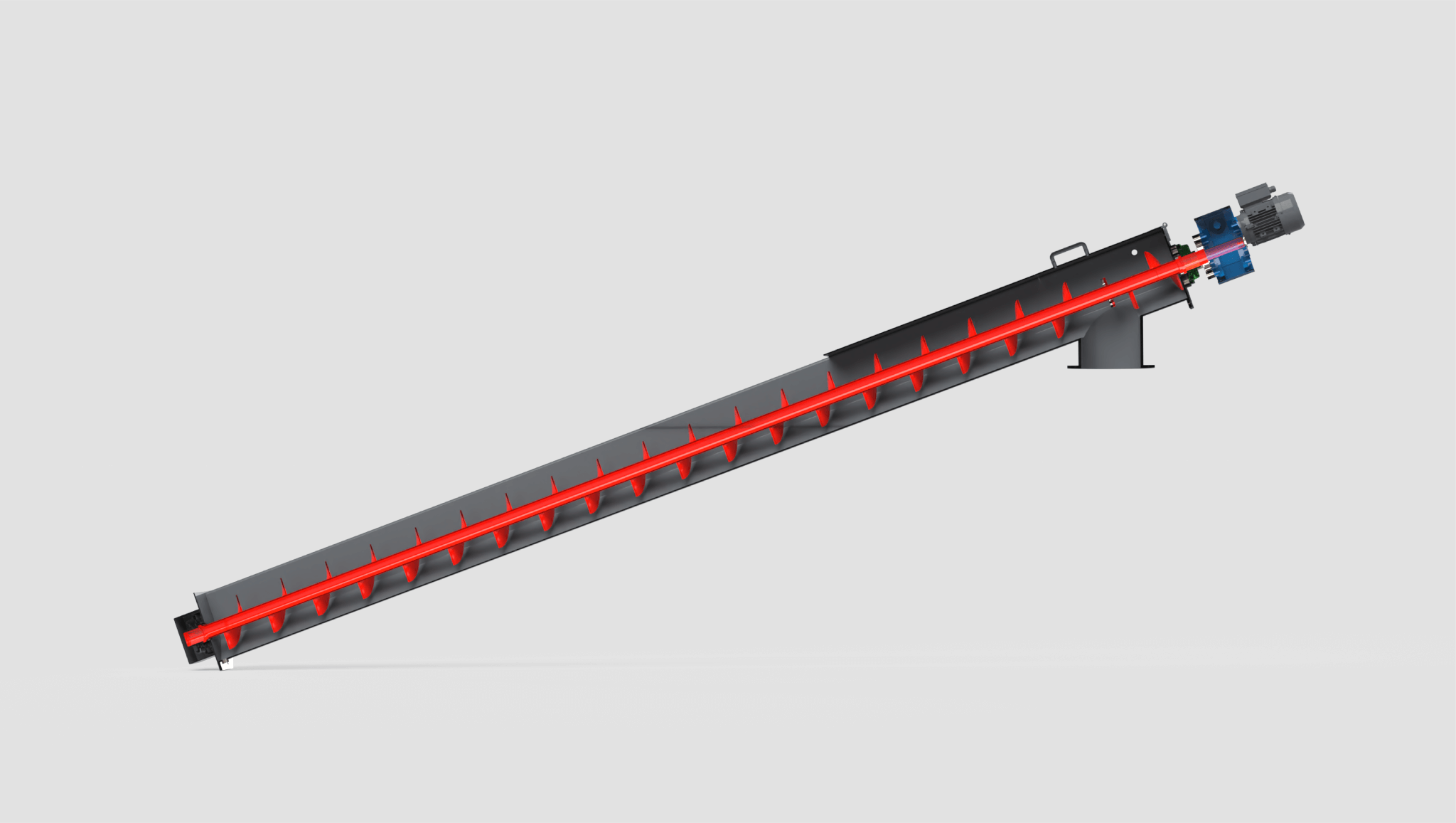

Stage two

The hopper auger is fixed to the bottom of the hopper and moves woodchip up to the top of the rotary valve.

- High torque double worm gear motor

- 6mm welded auger flights for strength and longevity

- Bespoke auger design for fast and efficient movement of wood chip

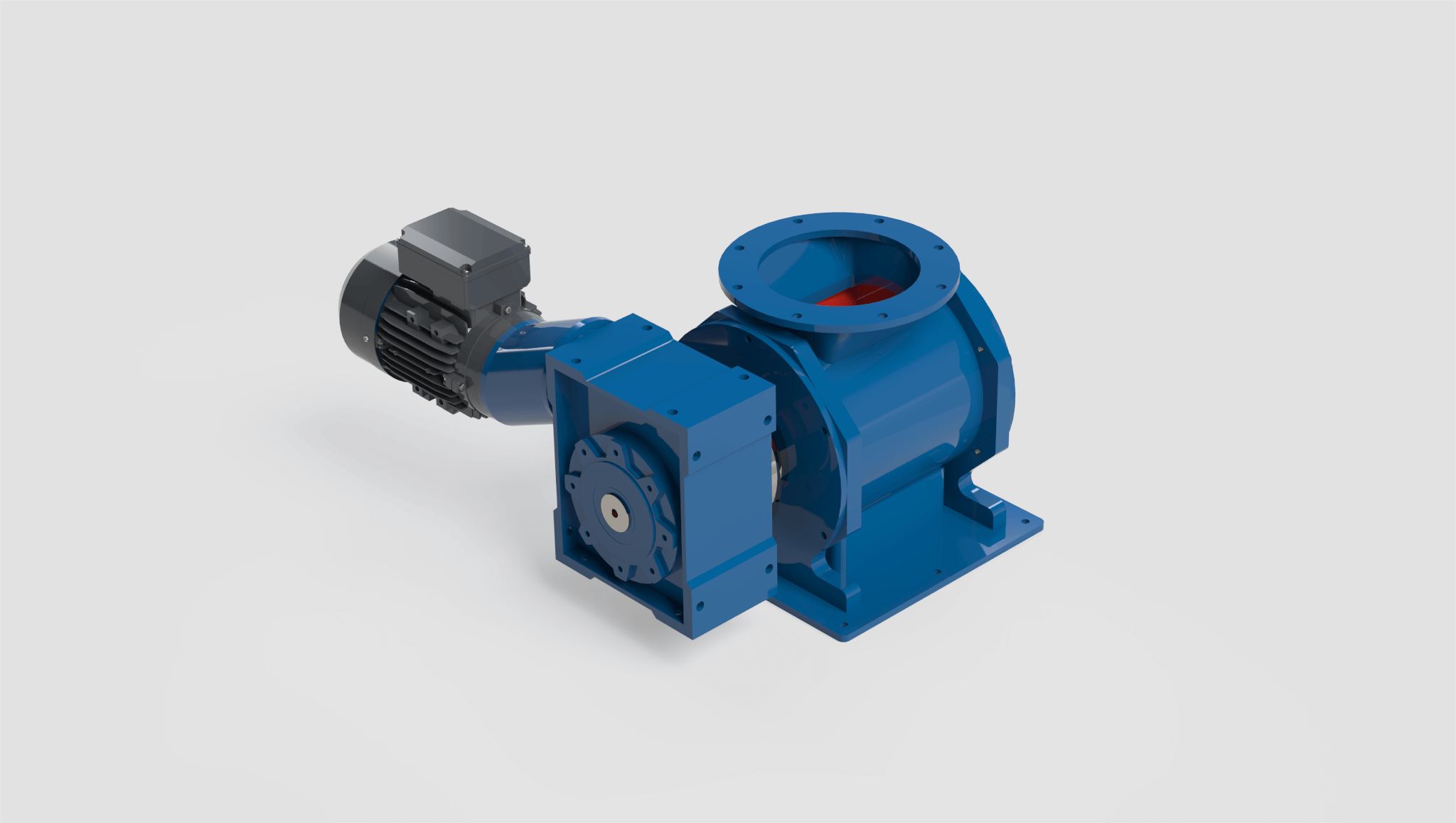

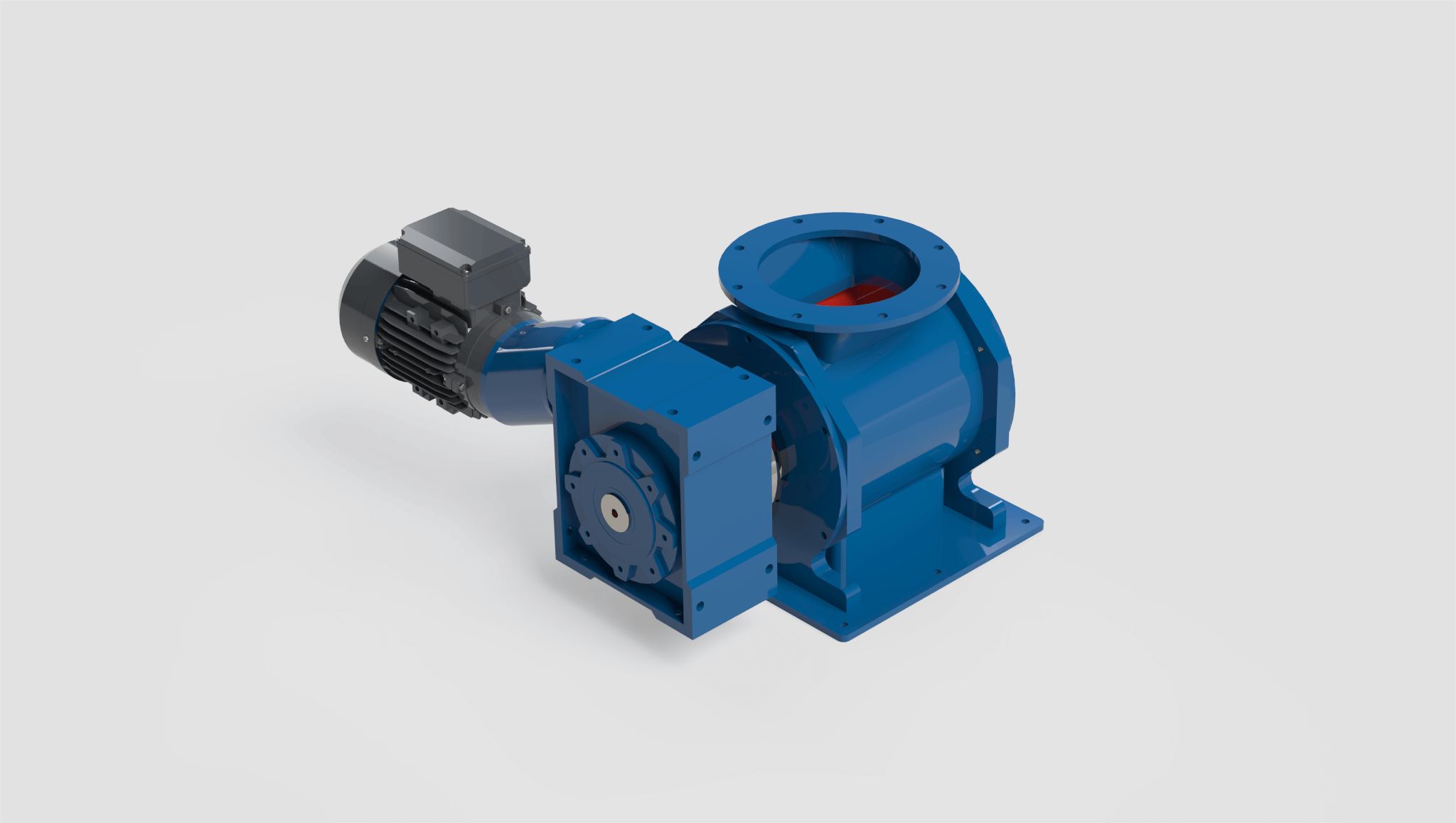

Stage three

Woodchip falls vertically into the rotary valve which acts as a permanent fire break.

- Hardened steel blades

- Oversized woodchip is chopped down to size

- Solid steel shaft

- High torque double reduction helictical pre-stage and worm gear box motor

- Fully powder coated outer for weather protection

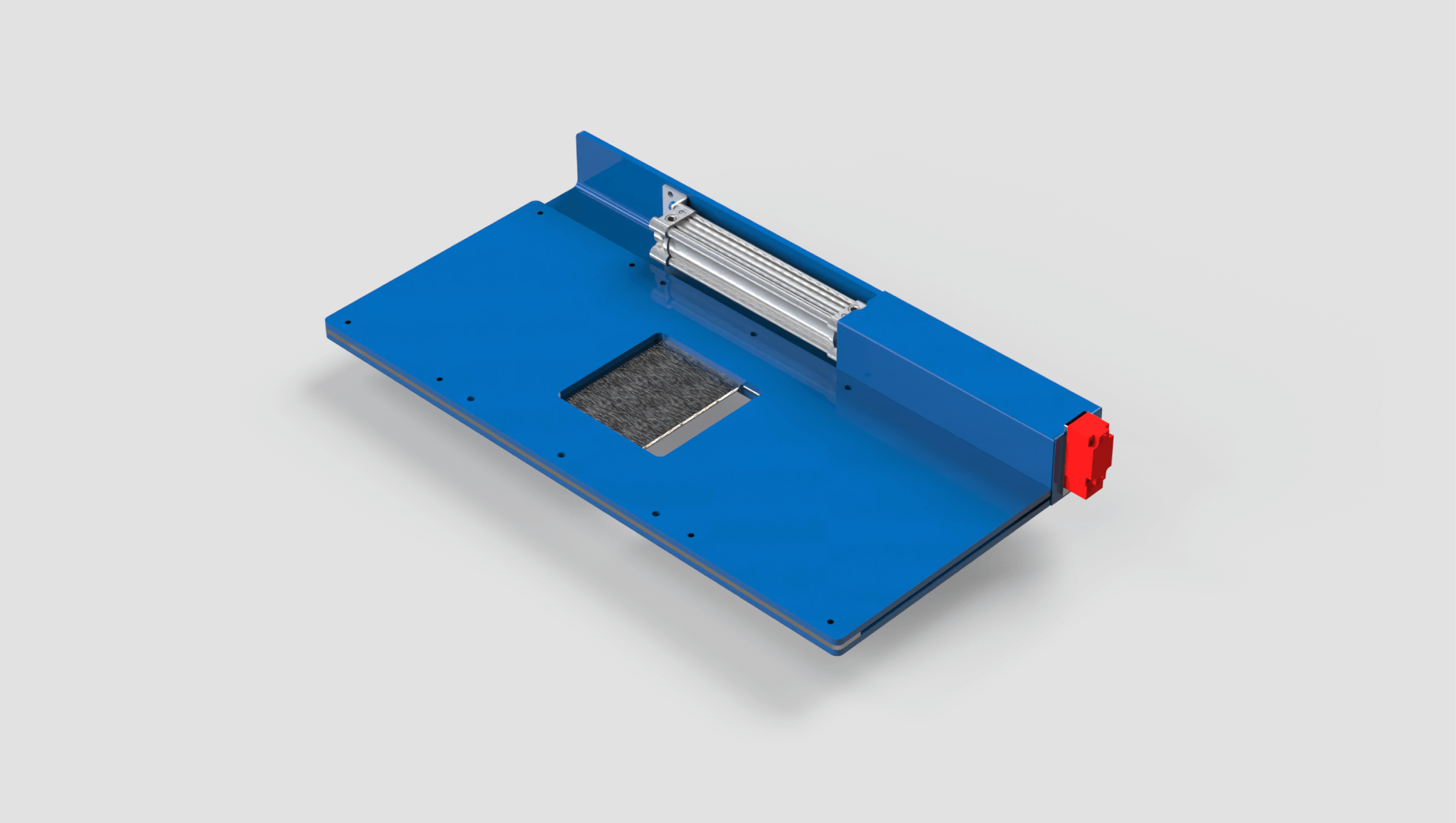

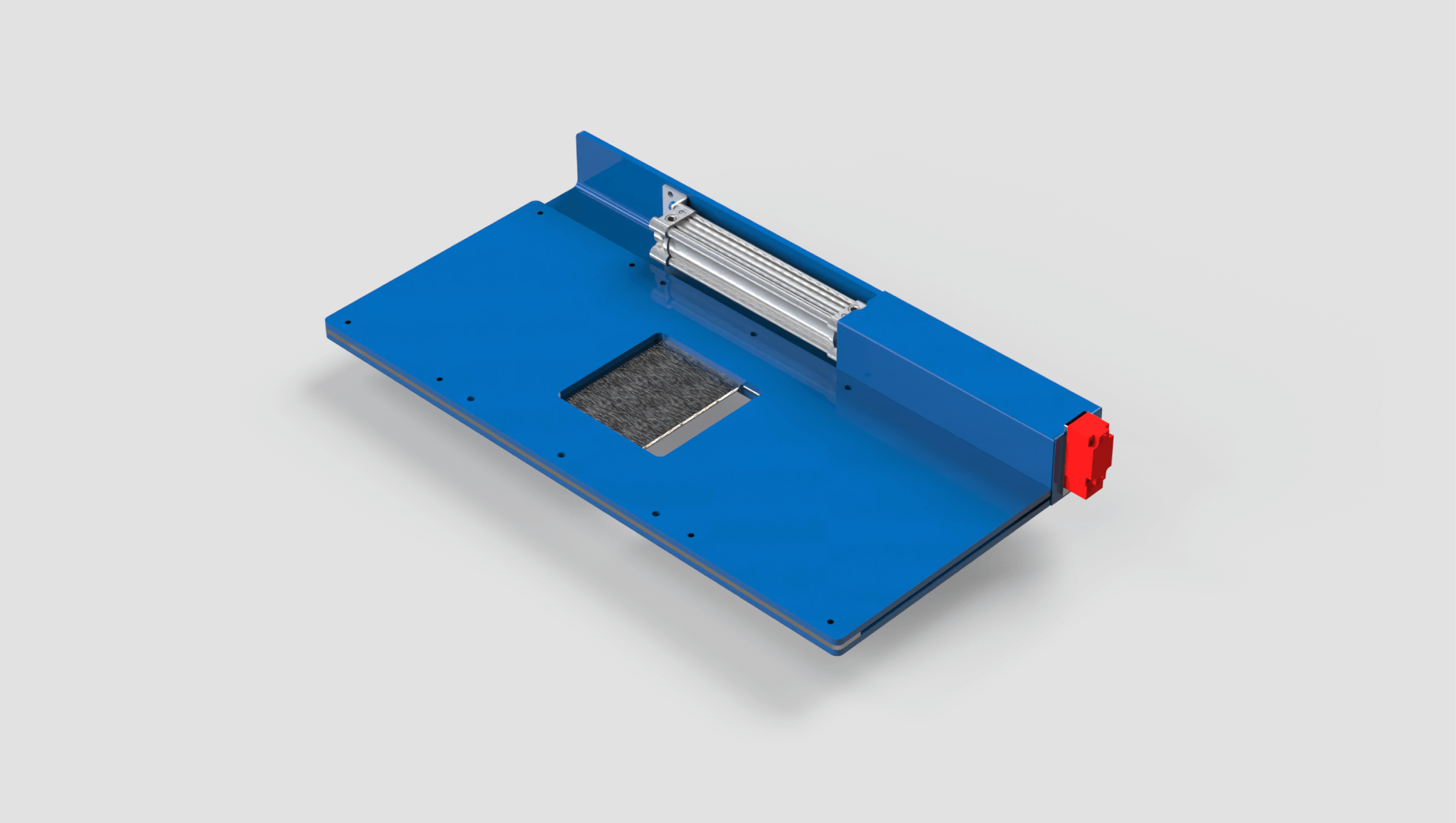

Stage four

Woodchip passes through the pneumatic knife valve. When the rotary valve comes to a stop the knife valve closes automatically.

- High temperature and abrasion resistant

- Graphite seal and fast acting pneumatic actuator

- Close protection by means of an electrical limit switch

- Stainless steel knife blade

Stage five

Stoker auger controls the flow of the woodchip directly into the combustion chamber of the boiler.

- High torque worm gear motor

- 6mm welded auger flights for strength and longevity

- Bespoke auger design for fast and efficient movement of woodchip

- Boiler plate components on entry to the combustion chamber