https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_a34752031d7e00ea4b30b00d59bfcdc5.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_c2dacf8fc008140f5188e561fd68bb54.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_99813327ad068f1858bcf1fc142649cf.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_8b212704ad91852dcc121c1cec6d51c5.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_1581daf59e4f4692066f1460facc6775.js

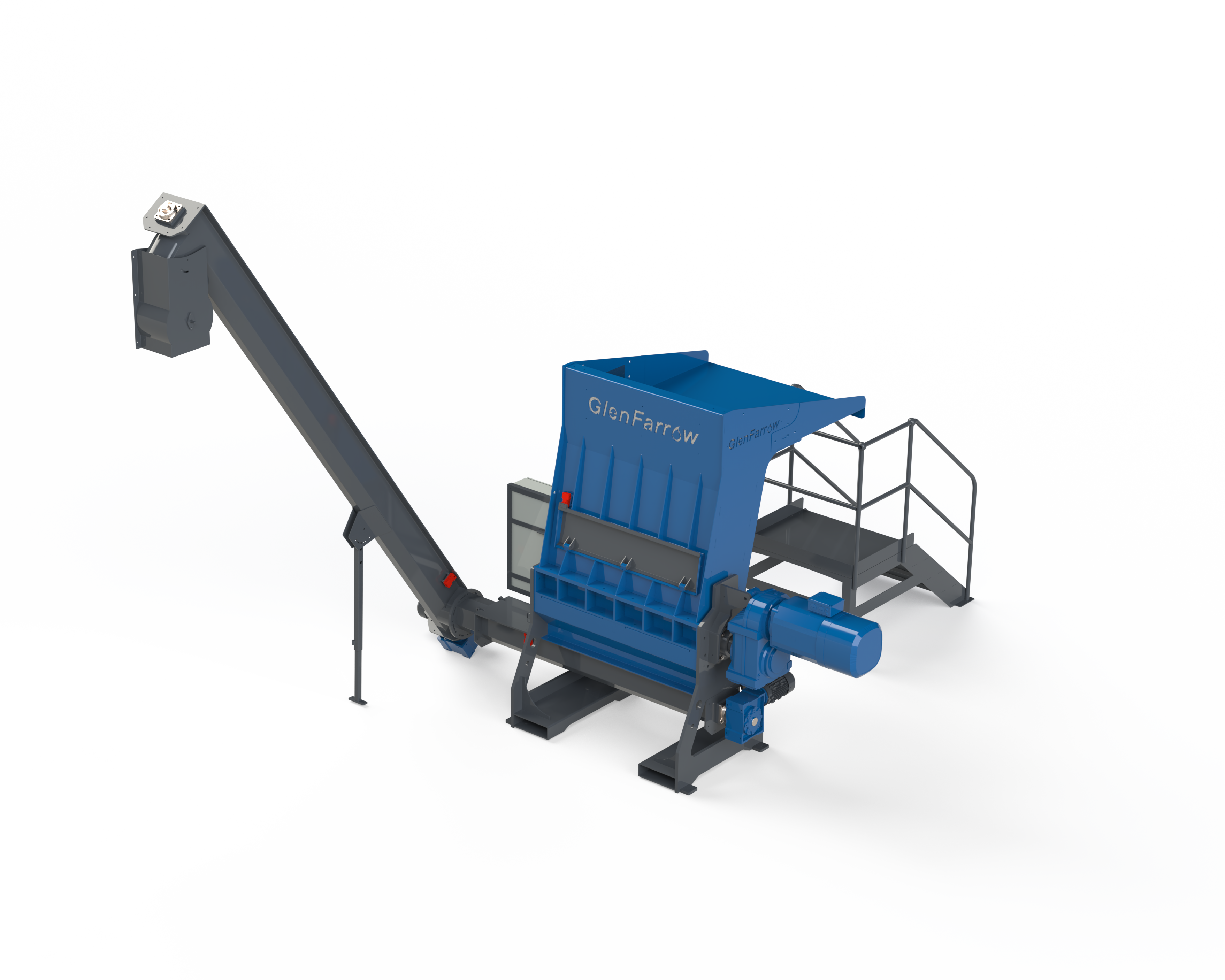

Benefits:

- Solid steel shaft with 1,400mm wide chipping area

- 29 hardened teeth that can be turned four times to prolong service life and reduce costs

- Large infeed chute to accommodate a variety of wood products and sizes

- Steel construction steps for easy loading

- Cross auger for fast clearance of material

- Incline auger for automated loading of hoppers, bulk storage and bags

- 3 phase electric motor with gear box

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_efc27e253fae1b7b891fb5a40e687768.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_917602d642f84a211838f0c1757c4dc1.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_e3317d55ad904d30ea400a2da2a56686.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_177c80d2ef791f8d5f89da73a3083f58.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_272f14f5de9caca54765bb008b7e660d.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_416f52248a7f5b988d66f1ea80a196ce.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_f9e0a162081d9b932df3807dd7a607a0.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_5480f11a9755afeba769fb68b05f0673.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_67d30ff80f55c60e95060d42c8d77c17.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_ea7c1d408be43a82a08a1ff4ecdf01cd.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_99e6b37c0dc5ccea287cb1ccd2fb8bf3.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_6878ecd5578aae4ef00a7ac088124852.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_491e30e5fa01d38078b77a77b44ef436.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_90c654122ae89d1835b64b0d2177c572.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_b113830baca96232dcde5b67dd4df13b.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_b113830baca96232dcde5b67dd4df13b.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_b113830baca96232dcde5b67dd4df13b.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_b113830baca96232dcde5b67dd4df13b.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_9eecb7db59d16c80417c72d1e1f4fbf1.js

https://glenfarrow.co.uk/wp-content/cache/breeze-minification/js/breeze_b113830baca96232dcde5b67dd4df13b.js