Whether a plant discharges its waste water into a water course or sewerage system, it will need to be accurately measured with a flow meter. However, there is not a ‘one size fits all’ approach to measuring flow rate. It is important that you have a meter best suited for your waste water. It is also typically a requirement of The Environment Agency and water companies to monitor your discharge.

Waste Water Manager, Andrius Lescinskas, has developed a guide for different flow meters to help you understand the advantages and disadvantages of different options.

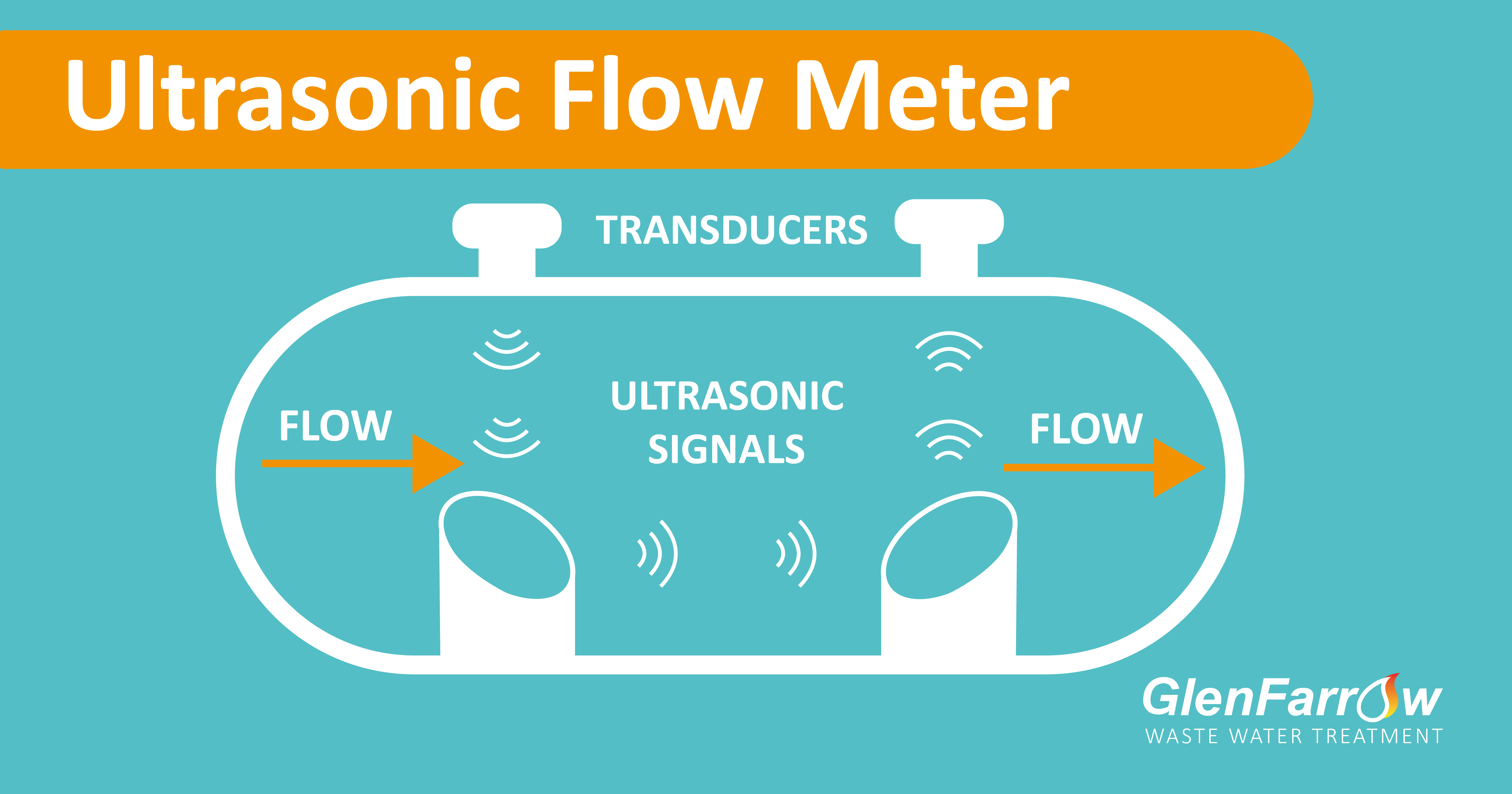

Ultrasonic flow meters

How they work:

Ultrasonic flow meters are currently the most commonly used meter to measure waste water. The flow meter body has ultrasonic transducers (little pins) sitting in the flow and they emit ultrasonic sound signals. The flow rate and volume is then measured by its disruption to the signal.

Advantages

👍 Very accurate measurements

👍 Low disturbance to the flow

👍 Low maintenance due to the lack of moving parts

Disadvantages

👎 Any change in the material will affect measuring accuracy as they are calibrated to a fixed density

👎 Accuracy may also be effected by air space in the pipe

Electromagnetic flow meters

How they work

Electromagnetic meters are very similar to the ultrasonic meters. However, instead of sound waves they use electromagnetic induction. There is an electromagnetic coil in the flow body that generates a magnetic field. The emitted electrodes capture the electromotive force (voltage), measuring the flow rate and volume.

Advantages

👍 Unaffected by temperature, pressure, density or viscosity of the liquid.

👍Able to detect contaminants

👍Very reliable as there are no moving parts

Disadvantages

👎 Cannot detect gases and liquids with electrical conductivity

👎 A short section of straight pipe is required for the installation

Turbine flow meters

How it works

In the body of the meter, water passes through a spinning turbine which turns the meter dials. The meter is provided with an electrical pick-up sensor which detects the rotation of the turbine. It then transforms the speed of the turbine into pulses, measuring the flow rate. Turbine meters are currently being used a lot less, with other meters being a more preferable choice.

Advantages

👍 Effective with clean water

Disadvantages

👎 Limited flow range

👎 Low tolerance for solids

👎 Restricts the water flow

Open Channel flow meters

This method is used where it is not possible or too difficult to install mounted meters. Using either ultrasonic, microwave or radar technology, open channel flow meters are placed over streams and channels. They effectively measure the height of the water flow through the channel. When the parameters of the water are unknown, this is the most appropriate way to calculate flow rate and volume when the correct commissioning formula is applied.

Advantages

👍 Long operational life

👍 Very accurate for both clean and waste water

Disadvantages

👎 Floating objects in the water can affect level measurement accuracy

If you require advice about flow meters for your plant, please contact Andrius on 01775 722327. To find out more about our waste water treatment services, click here: https://glenfarrow.co.uk/services/waste-water-treatment/